SKF, a renowned global manufacturer of bearings, seals, and related products, offers a range of wear sleeves designed to address the challenges of shaft wear, corrosion, and damage in various industrial applications. SKF wear sleeves, also known as shaft repair sleeves or sealing sleeves, provide an effective and efficient solution to extend the service life of machinery components.

Key Features and Benefits of SKF Wear Sleeves:

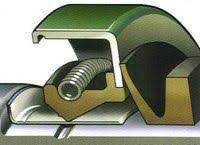

Shaft Surface Restoration: Over time, shafts can experience wear, scoring, or corrosion due to factors like friction, contaminants, and chemical exposure. SKF wear sleeves are designed to restore and enhance the surface of worn or damaged shafts, effectively providing a new sealing and bearing surface.

Easy Installation: Installing SKF wear sleeves is a straightforward process that does not require specialized equipment or skills. The sleeves can be easily slid onto the shaft, where they are pressed into place using a suitable tool. This simplicity speeds up maintenance procedures and minimizes downtime.

Optimal Sealing:In addition to repairing and protecting worn shafts, SKF wear sleeves contribute to effective sealing performance. The smooth, precise surface provided by the sleeve enhances the performance of radial shaft seals and other sealing elements, reducing the risk of fluid leaks and contamination ingress.

Corrosion Resistance: SKF wear sleeves are manufactured from high-quality materials, often stainless steel, that offer excellent resistance to corrosion, chemicals, and environmental factors. This ensures that the repaired shaft remains durable and reliable over an extended period.

Cost-Effective Solution: By salvaging worn shafts and avoiding the need for expensive shaft replacements, SKF wear sleeves offer a cost-effective way to extend the life of machinery and equipment. This leads to significant savings in terms of both time and money.

Versatility: SKF wear sleeves are available in various sizes and dimensions to accommodate different shaft diameters and repair requirements. This versatility allows them to be used in a wide range of industries and applications, from industrial machinery to automotive components.

Longevity: Thanks to their durable materials and precision engineering, SKF wear sleeves provide a long-lasting solution that withstands the rigors of demanding operating conditions.

In conclusion, SKF wear sleeves stand as a testament to the company's commitment to innovation and addressing real-world engineering challenges. By restoring worn or damaged shafts and enhancing sealing performance, these sleeves contribute to machinery reliability, reduced maintenance costs, and extended operational life. As industries continue to seek ways to optimize their equipment, SKF wear sleeves play a vital role in ensuring the longevity and performance of critical machinery components.